The Delft Solids Solutions laboratory is also engaged in materials development in the areas of micro-, meso- and combined porous materials, especially zeolites.

Zeolites are well known in catalysis for their unique combination of properties, such as hydrothermal stability, internal acid strength and the ability to apply shape selectivity. However, the purely microporous nature often leads to intra-crystalline transport limitations and therefore a significant volume of zeolite is ineffective in most catalytic applications. The introduction of mesoporosity in the purely microporous matrix leads to a better utilization of the volumes of zeolite and thus a greater effective catalyst.

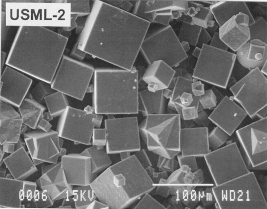

Although several approaches can be used to synthesize combined micro- and mesoporous zeolites, we have developed and further optimized the “desilication” method in our research laboratory. Desilication is the controlled extraction of silicon from the zeolite, usually in an alkaline medium, and thus different families of mesoporous zeolites (MFI, mordenite, beta, ZSM-12) can be prepared.

This method has proven very effective in improving catalyst performance for the conversion of the two bulky molecules into heavy gasoil and lighter hydrocarbons such as propylene and ethylene. Due to its simplicity and chemically controlled nature, this method is also easily scalable and suitable for field application.

Upon request, Delft Solids Solutions can prepare various combined microporous and mesoporous zeolites for initial testing. Please contact us for more information.