The majority of industrial materials and products consist of solids and powders. Particle sizing, size distribution and particle shape are important physical characteristics that highly influence the behavior during processing and handling of powders, like flowability, mixing, transport, caking, and storage. Laboratory particle size analysis by characterization of size distribution and shape is a strong tool in R&D and Quality Control environment and important in various areas such as: crystal growth, ceramic and alloy properties, emulsions stability, taste experience, catalyst activity, paint appearance and performance, waste water management, and so forth. Accordingly, these particle size analysis techniques are frequently practiced in pharmaceutical industry, food and feed industry and the chemical and petrochemical industry.

Closely related to particle size analysis is the droplet size distribution of sprays, nebulizers and other aerosols. Droplet size analysis is mainly used to optimize nozzle design, enhance inkjet printing technology, restrict excessive use of pesticides and increase medicine effectiveness. Smaller size droplets can provide a much higher effectiveness if they reach the right targets in the body – this all can be supported by selecting the most appropriate particle size analysis technique.

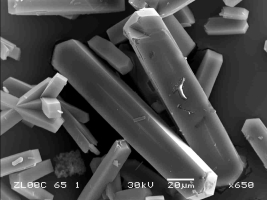

We offer various modern particle size analysis techniques such as Laser Diffraction, Electrical Sensing Zone, Photon Correlation Spectroscopy, Image Analysis, and Scanning Electron Microscopy in our analysis laboratory for particle size analysis. Our laboratory also employs more conventional particle sizing methods such as Sedimentation and Sieve Analysis for particle size analysis. Especially the sieving methodology enables a more facile correlation with industry where this particle size analysis tool is frequently used on larger scales. Selection of the most appropriate particle size analysis technique depends on the particle size range and the resolution required.

The presence of all these techniques enables to obtain particle size distribution information over a wide particle size range from nanometers to millimeters and depending on the particle size analysis technique this can be achieved with very high particle size resolution. Laser diffraction analysis e.g. offers a very wide size range for its particle size analysis with still a decent resolution whereas electrical sensing zone displays a fenomenal resolution (even down to sub-micrometer) at the cost of the overall particle size range that can be covered in a single particle size analysis measurement. Coupling of different analysis aperture tubes over the same sample can partly overcome the latter drawback.

We always aim at investigation of the particle size distribution under conditions that best match the practical application or use of the respective material and that answers the underlying research question. This means that the particle size analysis can be executed under dry conditions (in air) or upon dispersion in a suitable liquid that can be water but also non-polar media or organic media like ethanol, isopropylalcohol, cyclohexane, butanol and many others. Also temperature and humidity can be an important parameter in particle size analysis and this all should always be seriously considered when selecting the best particle size analysis conditions.

Particle size analysis questions

Offering the most appropriate particle size analysis conditions not only implies selecting a certain particle size analysis technique but also consider the right analysis conditions! Please contact us for a suitable advice on your particle size analysis questions.